Why do we use only urad dal (black gram) for idlis?

Have you ever wondered why we only use urad dal to make idlis? Why not use other pulses? It is because urad dal (black gram or black lentil) has some specific properties that other pulses don’t have. (Of course, we have rava idlis and moong dal idlis which do not use rice and do not involve fermentation. For air bubbles, these recipes use leavening agents like baking soda or eno fruit salt. But we are discussing the classic idli recipe in this post).

Here are the special properties of urad dal that are not commonly found in other pulses:

Foaming

After urad dal is soaked in water for at least 2 hours and ground in a wet grinder, it fluffs up to about 3 times in volume compared to the volume of the dry grains and water you start with.

.

This increase in volume is mainly because urad dal traps air and turns the batter into a foam. How does this happen?

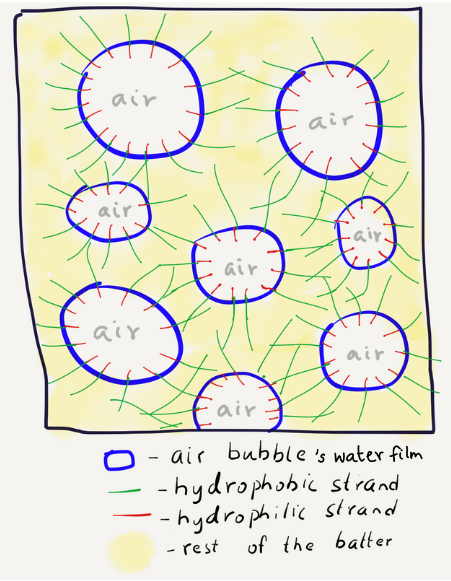

Even when you agitate plain water, you would see air bubbles forming on the surface. But these bubbles pop quickly since air has a tendency to escape. The water on its own does not trap the air because water molecules are electrically attracted to each other rather than to the air. So the bubble film breaks quickly.

Why don’t the bubbles in the urad batter escape so easily? Let’s zoom in and look at each air bubble closely. Urad dal is rich in a family of proteins called globulin. These proteins have a water-loving (hydrophilic) end and a water-repelling (hydrophobic) end. The water-loving end attaches itself to the water-side of a bubble’s film, whereas the water-repelling end is forced to the air-side of the bubble.

As the wet grinder keeps rotating and crushing the batter, the protein molecules get physically agitated and their long chains unravel. The water-repelling strands link up together to form a network which traps the air bubbles within them. (This kind of mechanical action and unravelling of proteins does not happen in a mixie. Which is why urad batters don’t foam up as much when ground in a mixie).

Since this happens at the surface of the air-water interface of each bubble, this phenomenon is called surface activity and such proteins are called surface active proteins. Another popular example of such foaming activity is how egg whites foam up when you whisk them.

Stabilising

But even foams created this way will not stay like that for long, on their own. They need another class of chemicals called ‘stabilisers’ to keep the foam together. Powdered sugar and cream of tartar are commonly added to whipped egg whites to stabilise the foam.

The speciality of urad dal is that it comes with its own built-in stabiliser! If you have cleaned up a sticky mixie jar or a messy wet grinder after grinding urad dal, you have dealt with what I am referring to. Urad dal has this class of carbohydrates / polysaccharides called arabinogalactan which make the batter very sticky (or mucilaginous, in food science terms). This sticky substance keeps the foam stable and also helps in trapping the gas produced during fermentation (CO2). The other advantage of this sticky substance is that it acts like a glue, holding the starch granules in the rice batter together with the rest of the batter.

Without this, imagine what would happen. Idli batter has three constituents – rice batter, urad batter and water – which have different densities. Rice batter is the heaviest and urad batter is the lightest, with water in between. Left on its own, the rice will settle down at the bottom, the urad will rise to the top. The foam will separate and this separation will let the gas escape.

Thus, only because of arabinogalactan, the foam stays put, traps gas and rises in volume on fermentation.

Withstanding Acid & Heat

You would have noticed that idli batter slightly thickens after fermentation. One reason for this is that the additional gas produced during fermentation increases viscosity (resistance to flow) – so the batter feels thicker. But the other main reason is to do with arabinogalactan. This sticky substance becomes even more viscous at lower pH (especially around 5.0, which is typical for idli batter around 12 hours of fermentation at room temperature). If this were not the case – ie., if this polysaccharide were to weaken during fermentation, we would not be able to make idlis in their current manner using fermented batter.

The arabinogalactan mucilage is also heat-stable, meaning it does not collapse when exposed to high temperatures. When the idli batter is steamed, the arabinogalactan holds its place, with its stickiness holding the other components in place too. The starches in the batter gelatinise (cook), the proteins in the batter coagulate (cook), the air bubbles expand and pop. The water turns into steam and escapes, leaving behind a solid cooked sponge that we call the idli.

Other Substitutes Tested

So both the foaming and stabilisation action of urad dal (black gram) are essential for making idlis. Other pulses might have similar foaming properties, but they do not have both the gas-trapping and foam-stabilising properties that urad dal has. Researchers have tested substitutes like Great Northern beans, soy beans, flaxseed (linseed) and oilseeds. But most of these substitutes have either needed the addition of a foaming agent or a stabilising agent to work. In this example, “Defatted peanut and sesame flours in aqueous dispersions exhibit good surface activity ascribable to their protein content and comparable to that of black gram. Soy flour possesses twice as much surface activity as the other flours. Contrasted with black gram, foam matrices obtained with these dispersions are unstable to heat and have low viscosities. Addition of viscous polysaccharide stabilized the foam against thermal disruption. Oilseed flours appear to qualify as good alternatives for the surface active component and viscous hydrocolloids such as guar gum or gelatinized starch may be alternatives for the arabinogalactan of black gram. This combination effectively replaces the pulse in imparting the characteristic soft, spongy texture to leavened foods.”

Reading all this, I wonder how the idli recipe in its current form came into being in the first place. Very specific properties of the ingredients and techniques employed in every step suggest that the idli recipe could not have been invented by a happy accident. Whoever did those first careful observations and iterations must have been a genius scientist in their own way. What do you think?

As for my next plan on this – watch out for an experiment post testing all this theory to check the effect of using other pulses in the place of urad dal.

References

- Susheelamma, N. S. and Rao, M. V. L. (1979) Functional Role of the Arabinogalactan of Black Gram (Phaseolus Mungo) in the Texture of Leavened Foods (Steamed Puddings). Journal of Food Science, 44. pp. 1309-1313.

- REDDY, N.R., SATHE, S.K., PIERSON, M.D. and SALUNKHE, D.K. (1982), IDLI, AN INDIAN FERMENTED FOOD: A REVIEW. Journal of Food Quality, 5: 89-101. https://doi.org/10.1111/j.1745-4557.1982.tb00736.x

- Muralikrishna, G., U. Ramadas Bhat, and R. N. Tharanathan. “Functional Characteristics of the Mucilaginous Polysaccharides Derived from Cowpea (Vigna Sinensis), Black Gram (Phaseolus Mungo) and Linseed (Linum Usitatissimum).” Starch – Stärke 39, no. 4 (1987): 107–9. doi:10.1002/STAR.19870390402