How long to soak rice and urad dal for idlis?

Some idli recipes ask for a minimum of 4 hours soaking time. Others say not to soak rice and dal beyond 2 hours. And yet there are cooks who routinely do an overnight soak. Does the soaking duration really matter? The answer to this depends on knowing what changes actually happen during soaking. And how much of these changes you want to happen.

visible changes

The first tangible effect of soaking is that rice and urad dal (black gram) grains absorb water and swell. Because of this, they become softer and easier to grind. Try crushing the dry grains and the soaked ones between your fingers and you will feel the difference. So, by soaking, we are making changes to the physical properties of the grains (changing them from hard to soft, dry to wet).

Notice how the rice has swelled only a bit whereas urad has plumped up quite a lot. (You would also have noticed that rice has turned from ‘glassy’ to a more solid white after soaking. The soaked version also shows some ‘cracks’ in the grain. This happens only with parboiled rice. We will cover this in a later post on why we use this specific type of parboiled rice for making idlis).

How much water gets absorbed

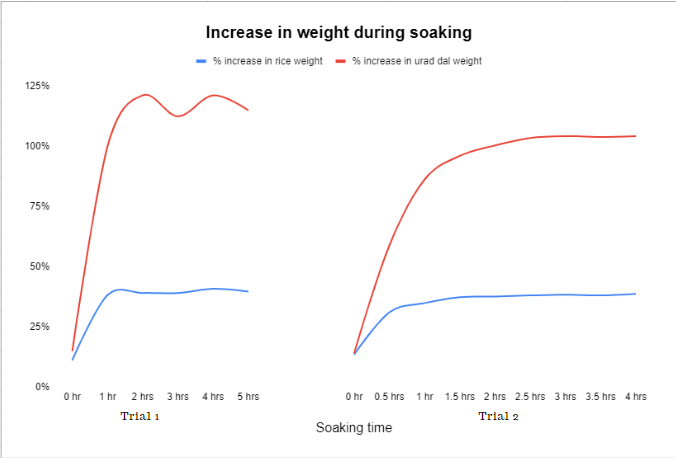

If the main purpose of soaking is just for the grains to absorb water, we need to find out when this absorption stops or maxes out. So, I weighed rice and dal at different soaking times.

For this, I washed and soaked rice and dal in separate containers (in my usual 4:1 ratio. Here’s why I use this ratio for idli). Every time I measured their weight, I drained out the water with a strainer and measured the weight of the grains alone. Then I added back the same water to the grains to continue the soaking. I did two trials of this on different days, using different batches of rice and urad dal, in different quantities. Here are the figures:

| TRIAL 1 | ||||

| Weight measured at different soaking durations | Rice (gm) | % increase in rice weight | Urad dal (gm) | % increase in urad dal weight |

| Before (dry weight) | 340 | 80 | ||

| 0 hr (just washed once) | 378 | 11% | 92 | 15% |

| 1 hr | 470 | 38% | 160 | 100% |

| 2 hrs | 473 | 39% | 177 | 121% |

| 3 hrs | 473 | 39% | 170 | 113% |

| 4 hrs | 479 | 41% | 177 | 121% |

| 5 hrs | 475 | 40% | 172 | 115% |

| TRIAL 2 | ||||

| Weight measured at different soaking durations | Rice (gm) | % increase in rice weight | Urad dal (gm) | % increase in urad dal weight |

| Before (dry weight) | 1039 | 255 | ||

| 0 hr (just washed once) | 1180 | 14% | 291 | 14% |

| 0.5 hrs | 1362 | 31% | 405 | 59% |

| 1 hr | 1402 | 35% | 475 | 86% |

| 1.5 hrs | 1427 | 37% | 500 | 96% |

| 2 hrs | 1430 | 38% | 511 | 100% |

| 2.5 hrs | 1435 | 38% | 519 | 104% |

| 3 hrs | 1438 | 38% | 521 | 104% |

| 3.5 hrs | 1435 | 38% | 520 | 104% |

| 4 hrs | 1442 | 39% | 521 | 104% |

It’s easier to draw conclusions when we see these figures plotted on a chart:

So, it looks like rice absorbs water to about 40% of its weight. While urad dal absorbs a whopping 100-120% ! No wonder it plumps up so much. It is also interesting to see that the bulk of the absorption happens in the first hour itself and almost stops after 2 hours of soaking.

So, if water absorption is the only reason to do it, I would stop at a 2 hour soak. But looks like there is more to it.

Structural Changes

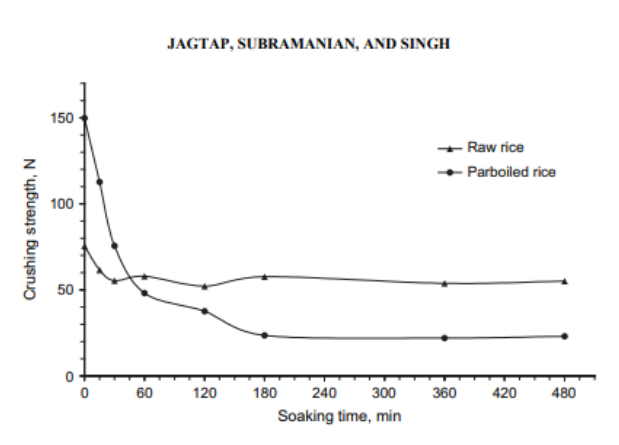

After water enters the grain, it starts making changes to the internal structure of the grain and this takes some time. From this paper: “Chiang and Yeh[15] showed that during soaking, protein, lipid and ash leaches out from the rice kernel. Further, their observations on the changes in microstructure of rice kernels during soaking revealed the disappearance of the protein matrix due to the penetration of water … thereby reducing the hardness of the rice kernel and making grinding the endosperm easier”. As a result, less force is required to grind the rice. “The crushing strength of unsoaked parboiled rice was 149.8 N and that of soaked for 3 h was 23.6 N. The reduction in crushing strength was significant (84%) after soaking for 3 h.”

The study has been done for IR-64 variety of rice. It would have been great to know the equivalent for the idli rice variety. But until I find out, I would soak rice for at least 3 hours for better energy efficiency during grinding. Anyways, there seems to be no obvious downside to a slightly longer soak.

Soaking for too long does not result in any further water absorption or energy savings. But there are folks who strongly recommend a longer soak time. Could there be other reasons why they suggest it? Turns out, there might be a strong reason at least for urad dal.

Microbe Friends

Most of the microbes involved in the natural (wild) fermentation of idli batter come from urad dal. Did you know that at least 290 bacterial species are involved? Of course, not all of them play a significant role. And whichever species dominate, they do so at different times in the process. The two main characters are:

- Leuconostoc mesenteroides (the same bacteria that is involved in the setting of curd, kimchi fermentation, sauerkraut- making, etc). This acidifies the batter slightly in the initial stages by producing lactic acid, so that other harmful microbes don’t grow in the batter. During fermentation, it also produces gas (CO2) which makes the batter rise and gives idlis their spongy texture.

- Streptococcus faecalis (Now reclassified as Enterococcus faecalis). This is responsible for the increase in acidity levels in the batter after L. mesenteroides has done its initial job. The acidity gives idlis their characteristic sour-sweet smell and taste.

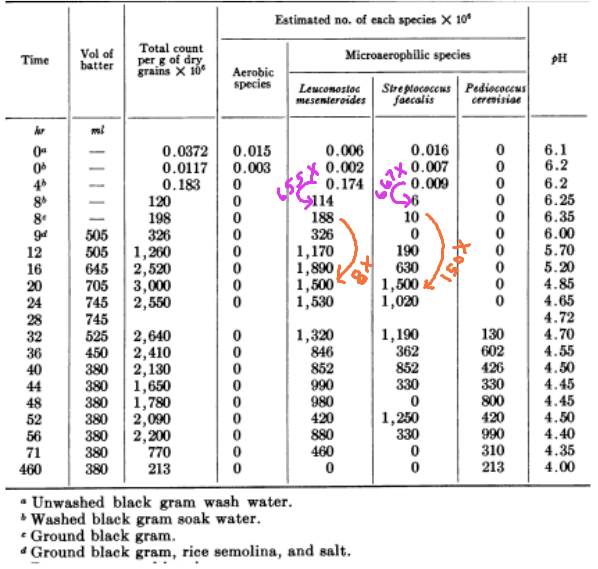

So, both these stars help in creating idlis’ taste and texture. Now, why are they relevant to our soaking-time discussion? It turns out that the count of these useful microbes increases by about 650 times between 4 to 8 hours of soaking urad dal in water. In contrast, the count increases by only a fraction of this in 12 hours of fermentation after rice semolina and salt are mixed in with urad batter (about 8 times for L.mesenteroides and 150 times for S.faecalis). So, soaking is when most of their growth happens!

Check out this table in this seminal paper published by S. K. Mukherjee, M. N. Albury, C. S. Pederson, A. G. Van Veen, And K. H. Steinkraus in 1964:

Maybe this is why some cooks prefer an overnight soak. Definitely worth a try.

As for cooks who ask you not to soak beyond 2 hours – maybe they live in places which have room temperatures at which these microbes thrive well. So they may not need the head start provided by a long soak. In fact, they might have more control and can avoid over-fermentation if they soak only for short durations.

I usually soak dal and rice for 4 hours before grinding. In my place, the room temperature is only about 20-25deg C. This is much lower than the temperature at which L. mesenteroides is most productive (~30deg C). So my batter sometimes takes more than 16 hours to reach the desired level of fermentation (by my smell test). I want to check if a long soak of dal can speed up the fermentation. Watch out for an experiment post on this.

For now, I wonder whether the 650-fold increase only happens when urad dal remains soaked in water in the form of whole grains. Or, does it happen at the same rate after it is ground too? And why does the rate reduce after rice batter is mixed in? Shouldn’t it rather increase, given the microbes will now have more food?

Do you know of other reasons why a particular soaking duration is recommended? Please drop a comment!

References

- P.S. Jagtap , R. Subramanian & Vasudeva Singh (2008) Influence of Soaking on Crushing Strength of Raw and Parboiled Rice, International Journal of Food Properties, 11:1, 127-136

- Role of Leuconostoc mesenteroides in Leavening the Batter of Idli, a Fermented Food of India1 S. K. MUKHERJEE, M. N. ALBURY, C. S. PEDERSON, A. G. VAN VEEN, AND K. H. STEINKRAUS New York State Agricultural Experiment Station, Cornell University, Geneva, New York, 1964.